SHREDDERS AND GRINDERS

Providing units designed for performance, reliability, efficiency, and low maintenance

Our shredders and grinders are cost efficient, durable, and capable of processing whole animals with no cutting required. Our grinders and shredders are available in a variety of models and sizes that can be customized to your company’s specifications.

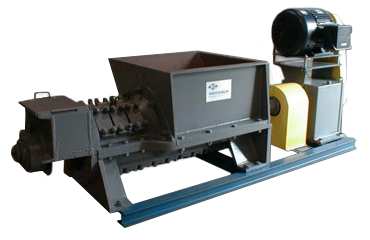

1045 Crusher

The ANCO 1045 Crusher is one of the largest pre-breakers in the industry, handling size capabilities of up to 80,000 lbs. per hour without precutting whole animals. The 1045 Crusher has the longest life expectancy of any Crusher in the rendering industry, while remaining cost efficient. Using the latest metallurgical technology, the cast alloy steel parts are stronger than any other on the market. Each hammer is individually machined, producing a scissoring effect when combined with the anvil. The sharp hammers can slice through large bones or soft material, while providing a uniform particle size. The 120 RPM shaft speed assures low impact stress to the unit. The Crusher comes equipped with:

- A 125HP low RPM motor with a 38 ½” opening.

- Outboard pillow block bearing designed to reduce shaft deflection, jamming, and wear on the hammer and anvil.

Duracut Crusher and Bone Shredder

The ANCO Duracut Crusher is designed specifically for bone or whole carcass crushing. The Duracut unit has a one-pass design that emits a particle size suitable for feeding any conveying or pumping system. These particles are small enough for any batch or continuous rendering system. The Duracut Crusher can process up to 50 tons of raw material per hour and the inline design makes for easy installation, maintenance, and operation. The Duracut unit can be customized with:

- A control panel with PLC, touch screen and motor starters.

- Multiple teeth design and configurations for optimum performance.

- Two-year warranty on motor and drive assembly.

- Easily changeable configurations, making it easily adaptable to both new and existing installation.

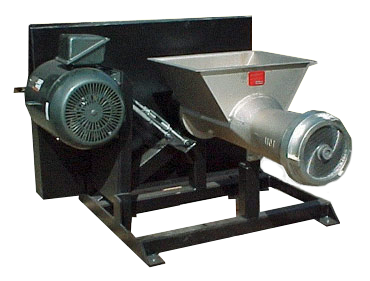

1101 DOA Grinder

Whether the product involves seafood, poultry, meat, pet food, or any other processing application, ANCO grinders are available in a variety of sizes and models to meet your production needs. Each unit is custom built to your specifications and provides trouble-free production, hour after hour. The ANCO 1101 grinder series can also be fitted with a Positive Displacement Pump to grind and transfer your product in one application. Each 1101 DOA Grinder comes outfitted with:

- A large capacity hopper, that can hold up to 100 lbs. at a time.

- Automatic fast feeding, without clogging or jams.

- No heat build-up or product cooking.

- Complete grind control, with a patented screw and barrel design.

- Quick clean-up to meet all U.S.D.A. standards.

- Outstanding flexibility provided by 25-100 HP motors with varying feeds and RPMs.

DOA Crusher

The ANCO DOA Crusher is an excellent product solution for size reduction applications. This unit can handle a variety of products and is designed to process difficult raw material that needs to be pumped. The ANCO DOA Crusher has the capability to grind whole pieces of 18”x18” down to 2”x2”. Each unit features double wall construction, automatic jam proofing, and full shaft diameters through the entire width of the machine and the outside of the supporting bearings. The ANCO DOA Crusher features:

- Light weight material.

- Turkey, poultry, pork jaw and skull, whole fish, small animal, wood and fibers, paper and cardboard, and medical waste processors.

801 Fish Grinder

ANCO provides customers with large capability, high production grinders designed to grind fresh and frozen products. Our grinders have a wide range of plate sizes that can be outfitted for a coarse or fine grind. The ANCO design allows for the addition of pumping systems and/or conveyors that can be easily incorporated into any new or existing unit.

ANCO grinders can be supplemented with a range of additional equipment, including double cut systems, triple plate assemblies, bone elimination systems, and transition funnels to suit any application. All ANCO grinders are manufactured in the USA and built for durability, maximum productivity, and easy maintenance with replaceable wear parts that are supported world-wide. Some additional ANCO grinder options include:

- CE marking, if required by country code.

- Tinned or stainless-steel construction.

878 Edible Grinder/Mincer

The ANCO 878 Edible Grinder and Mincer is manufactured with sanitary components to comply with U.S.D.A. and AG Canada standards. Specially designed to grind frozen meat, bones, sausage, and fat trimmings for edible applications, the 878 Edible Grinder and Mincer is engineered and designed for performance, reliability, efficiency, safety, and low maintenance. The low HP design and variety of size allows the 878 Edible Grinder and Mincer to process all meat and poultry in a gentle, clean manner. The ANCO unit can be customized with:

- Pet food grade applications.

- Optional double knife sets and bone elimination systems.