PRESSES

Maximizing your profitability and reducing moisture content with

our dewatering systems and presses

Presses

Materials generally enter the rendering process with 70% moisture. The most effective way to reduce moisture content is to mechanically dewater the material with our superior dewatering systems and presses.

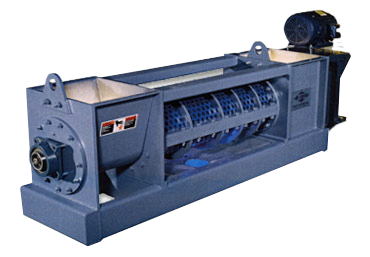

1270 Dewatering Press

With high fuel and operation costs, rendering plants need to maximize their operating efficiencies to reduce operation costs and improve profitability. With reduced steam costs, reduced hauling costs, and increased processing capacity, the 1270 Dewatering Press is a must-have for your company’s rendering applications. Utilizing a redesigned feeding system, the ANCO 1270 Dewatering Press substantially reduces water content from feathers with no plugging issues. Constructed from 1045 steel, the heavy-duty shaft is much stronger than the 1018 steel used by other manufacturers. The 1270 model includes:

- Higher service factors on the gearbox.

- Stronger splash guards, allowing for easy removal and lasting durability.

- Lift lugs for easy installation.

1271 Paunch Dewatering Press

Based on over 40 years of dewatering press experience, the ANCO 1271 Paunch Dewatering Press employs advanced technology and is an effective solution to reducing water load in a packing house paunch. The 1271 Paunch Dewatering Press processes up to 90 cows per hour, respectively dewatering 7,000-18,000 lbs. per hour from an initial 8-10% DS to greater than 40-45% DS. Low HP power demands range from 7.5-20 HP, offering a solution to daily paunch disposal costs. This unit can be automated with a PLC and touch screen to substantially reduce overall operation costs.

202 Screw Press

ANCO’s revolutionary 202 Screw Press family is leading development in pressing protein-conversion products. In addition to the original 202 Screw Press and the 202-4 Screw Press, three new machines have been constructed to meet more diverse production needs. Our units range from the 202-3 Screw Press, for small production needs of 1-1.5 tons per hour, to the 202-8 Screw Press, which press 4 tons per hour.