DRYERS

Providing units designed for performance, reliability, efficiency, and low maintenance

ANCO dryers are well-suited for any type of industry and product. The compact and adaptable design makes it easy and efficient to upgrade from older evaporation equipment.

AE300SS Continuous Disc Cooker/Dryer

The ANCO AE300SS is designed for continuous cooking/drying of the by-products of animal processing. The internal rotor pipe is fitted with a sequence of chambers formed by discs that are secured and welded together. Steam is then fed through the rotor pipe and into the disc chambers creating a large heated surface area. Raw material passes through the unit coming in to contact with the heated surfaces of the rotor assembly causing the product temperature to rise. The rotor assembly is rotated to ensure maximum surface contact of the material passing through the unit. The vapor is formed by the evaporation of water from the product and is collected in the vapor dome for removal. Our “Sure-Plate” disc design is unique to the ANCO line of continuous cookers. This unique design allows for higher corrosion allowances and has higher pressure ratings than our competitors. With the Sure-Plate design, the rotor and discs are self-contained and require no costly repair or re-weld on the discs.

The entire pressure vessel is fabricated and tested to ASME Pressure Vessel code:

- Designed for continuous cooking/drying of by-products.

- Larger heated surface area.

- Unique “sure-plate” disc design for higher corrosion allowances.

- Higher pressure ratings and less maintenance.

- ASME pressure vessel code approved.

- No costly repairs or re-welds on discs.

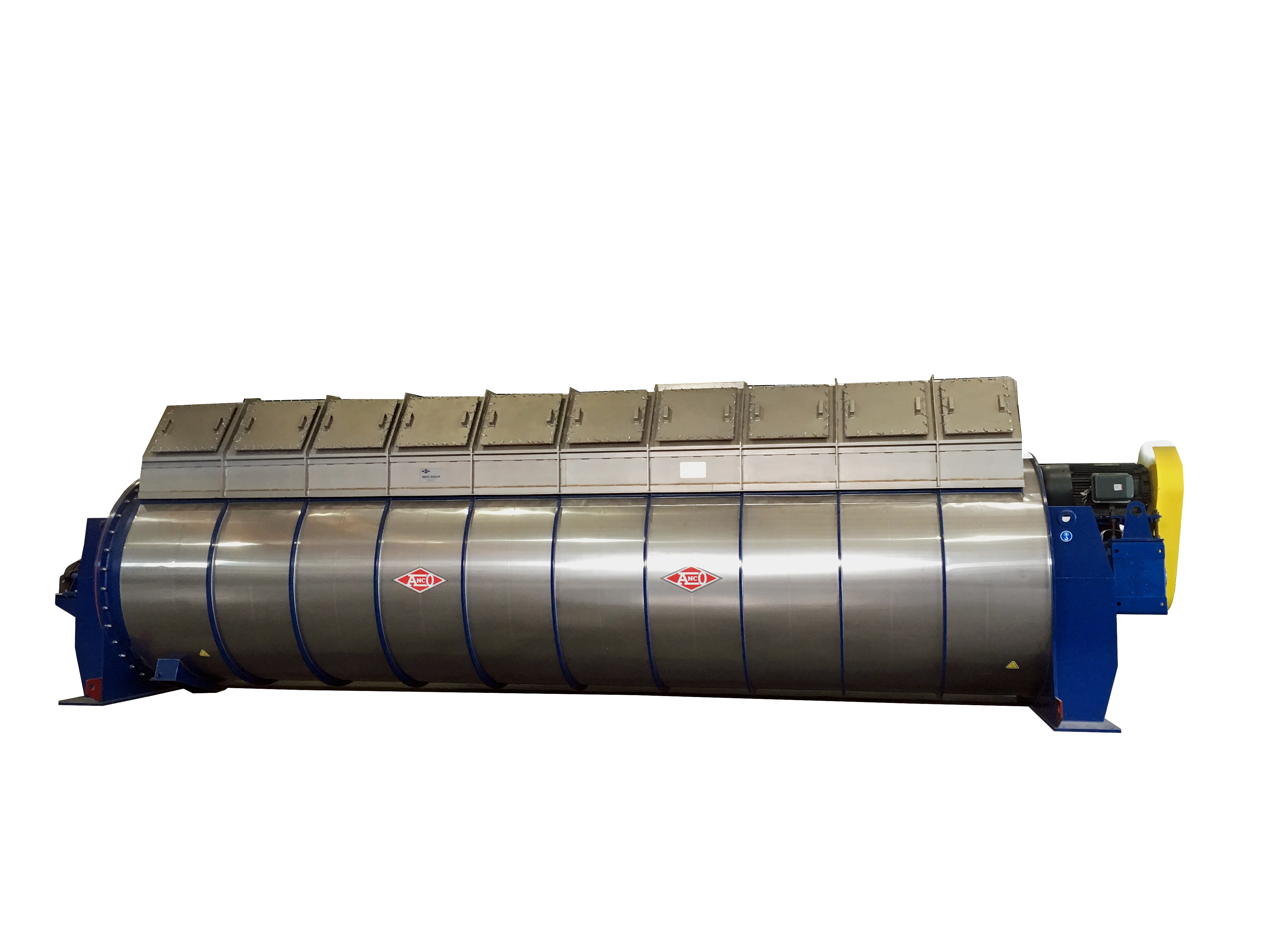

Sure Plate Continuous Disc Dryer

ANCO Sure Plate Continuous Disc Dryer utilize indirect, continuous drying combined with maximum heated surface area in a minimum space. The rotor consists of a tubular shaft with multiple disc to heat and transport product. ANCO also offers a Sure Plate design with no external welds on the central heating surface. This superior construction has a greater pressure aspect and can handle over double the pressure of other conventional designs. The ANCO Disc Dryer features:

- Up to 4400ft^2 of heat transferred surface area.

- Up to 3200ft^2 for the Sure Plate design.

- Standard disc edge wear band design.

- Minimal welds and optimum heat transfer design.

- Optional stainless-steel construction, mechanical seals, U.S.D.A. or AG Canada designs, and varying disc thickness.

Direct Fired Dryers

ANCO Direct Fired Dryers employ rotary drum dryers along solid fuel burners and waste heat recovery systems. Whether you need to render animal feed, forest products, or distillery/brewery waste, our engineering staff can assist with your custom application. The Direct Fired Dryers feature:

- 5-60 million BTU per hour capabilities.

- Reduced operation and maintenance costs.

- Reduced emission levels and amount of air exhaust that required treatment.

- Open and safe design, to reduce plugging and fire hazards.

- Low HP design.

- 9% collection efficiency, with no need for wet scrubbers.

- PLC controlled for optimum performance.

Optional heat recovery system. - Stainless or carbon steel construction.

1600 Steam Tube Dryer

The ANCO model 1600 Steam Tube Dryer is designed specifically to dry poultry feathers, hog hair, and blood. When combined with a traditional ANCO Batch Cooker or Continuous Hydrolyzer, you can save production time, steam demand, and electrical consumption. The 1600 Steam Tube Dryer is well-suited for all types of free-flowing granular materials, such as chemicals, brewery waste, and minerals. The compact design makes the 1600 model an easy and efficient way to upgrade from older evaporation equipment. The 1600 Steam Tube Dryer features:

- Stainless-steel construction.

- 100 psig pressure rating for rotating tube bundles.

- Greater heat transfer surface area, with capabilities up to 1400 ft2

- Low HP design.

- Shaft mounted gearbox designed for durability.