COOKERS AND HYDROLYZERS

Leading the industry in cooking and hydrolyzing technology

Our cookers and hydrolyzers can function as batch or continuous units. Our equipment has been in operation for over 40 years of dependable production.

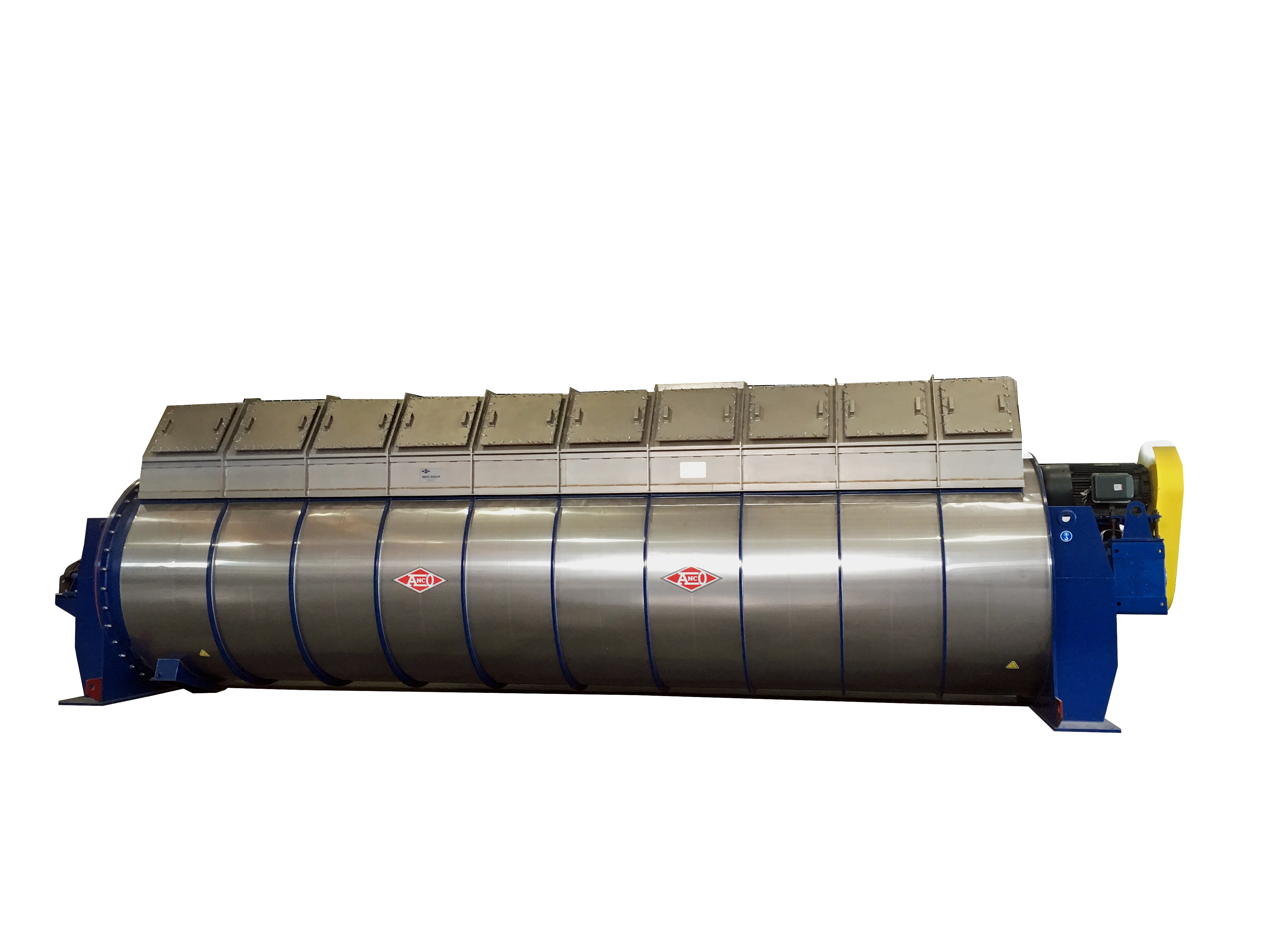

AE300SS Continuous Disc Cooker/Dryer

The ANCO AE300SS is designed for continuous cooking/drying of the by-products of animal processing. The internal rotor pipe is fitted with a sequence of chambers formed by discs that are secured and welded together. Steam is then fed through the rotor pipe and into the disc chambers creating a large heated surface area. Raw material passes through the unit coming in to contact with the heated surfaces of the rotor assembly causing the product temperature to rise. The rotor assembly is rotated to ensure maximum surface contact of the material passing through the unit. The vapor is formed by the evaporation of water from the product and is collected in the vapor dome for removal. Our “Sure-Plate” disc design is unique to the ANCO line of continuous cookers. This unique design allows for higher corrosion allowances and has higher pressure ratings than our competitors. With the Sure-Plate design, the rotor and discs are self-contained and require no costly repair or re-weld on the discs. The entire pressure vessel is fabricated and tested to ASME Pressure Vessel code.:

- Designed for continuous cooking/drying of by-products.

- Larger heated surface area.

- Unique “sure-plate” disc design for higher corrosion allowances.

- Higher pressure ratings and less maintenance .

- ASME pressure vessel code approved.

- No costly repairs or re-welds on discs.

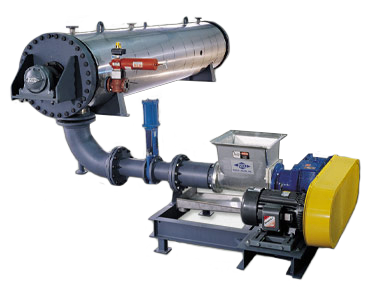

Fish Cooker and Pre-Heater

The ANCO Fish Cooker and Pre-Heater is a major development in fish rendering systems, as it provides an effective solution for quality variety in high yield, raw material. The ANCO pre-heater consists of a stator housing with a steam-heated jacket and a screw rotor with an indirectly steam heated continuous flight. The stator steam jacket is divided into sections, enabling uniform distribution of steam by a condensate manifold. The jacket includes a special design that utilizes hot condensate to heat a portion of the jacket, reducing energy and operational costs. The ANCO Fish Cooker and Pre-Heater features:

- Gentle heating prior to raw fish processing.

- Designed for a combination of indirect and direct steam heat sources.

- Energy efficient design provides optimal liquid and oil separation.

- Minimal maintenance costs, helping to ensure a continuous cooking operation.

- Low HP and minimal steam requirements.

- Optional stainless-steel construction.

1500 USDA/AG Canada Batch Cooker and Pre-Heater

The ANCO model 1500 Batch Cooker features a removeable front head and optional steam heated shaft to save floor space and provide for more heat transfer surface area than conventional cookers. In addition to drying at atmospheric pressure, it’s internal pressure design allows for a multitude of hydrolyzing and sterilizing applications. The 1500 Batch Cooker and Pre-Heater can be outfitted for the food, chemical, medical, and edible rendering industry. Constructed from the strongest material, including high grade 90,000 psi pressure vessel steel, and manufactured per ASME code, the 1500 model provides for exceptional safety, durability, longevity, performance, and overall value. Variable pressure rating designs and specialized material construction, from 304-316 stainless-steel, can be provided to accommodate customer’s needs. The 1500 Batch Cooker and Pre-Heater can be customized with:

- Automatic inlet and outlet material closures, moisture and temperature sensors, weighing cells, variable speed agitator, and time and temperature sterilization chart recorders.

- Linkage to a PLC automation controller, to save labor, eliminate operator error, and provide optimum product quality.

1212 Continuous Hydrolyzer

The ANCO 1212 Continuous Hydrolyzer is an integrated system with advanced PLC controls. This unit receives and continuously processes products requiring a hydrolysate phase change, such as poultry feathers and hog hair. This proven system turns by-products into profitable and digestible animal feed or ingredient additives. The ANCO 1212 design is proven with more years of experience than any other manufactured equipment in its class. The ANCO 1212 series features:

- Processing capabilities up to 30,000 lbs. per hour.

- Bottom Feed design, for easy maintenance, increased dewatering, and decreased spillage.

- Low emissions and minimal contributions to factory odors.

- Heavy-duty infeed drive, doubling the torque capabilities compared to the original drive.

- 5/8” thick stainless-steel inner shell wall.

- Employs 1 lbs. of steam is used for every 3 lbs. of raw feathers.

Batch Hydrolyzers

Built to ASME, CE, or EU specifications, ANCO Batch Hydrolyzers have the capability to process up to 12,000 L per batch. The Batch Hydrolyzer can also be used as a dryer or conditioner to reduce moisture content and can easily handle raw materials with high fat contents. This unit is designed to easily process a variety of raw materials and ensure complete hydrolyzation. ANCO units have the highest available pressure ratings and are constructed from the highest quality of materials. The Batch Hydrolyzer is constructed of ASTM 516-70 alloy steel with a tensile strength of 70,000 psi to 90,000 psi. This material is 27% stronger than materials used by competitors and provides a high jacket rating of 125 psi. Customize your Batch Hydrolyzer with:

- Optional factory installed S.S.

- Mechanical Seals, to reduce required maintenance and wear on the shaft.

- Optional increased pressure ratings for special applications.

- Designable for complete plant automation.

Batch Cooker

The ANCO batch cooker features a removable front head, optional steam heated shaft and compact design. It saves floor space and provides for more heat to be transferred to the surface. The internal pressure design also allows for it to be used for a multitude of hydrolyzing and sterilizing applications.

- Pow-R-Pak Shaft mounted gearbox (double seal design and higher rated bearings).

- Inner Shell constructed of ASTM 516-70 with a tensile strength of 90k PSI.

Capacities up 7000 liters.

Continuous Disc Cooker

The Continuous Disc Cooker is designed for continuous cooking or drying of fish or animal by-products. The Continuous Disc Cooker utilizes indirect, continuous thermal heat and low RPM to produce better quality end products and less fines, compared to tube style units. The rotor consists of a tubular shaft with multiple discs, designed to heat and transport the product with an excellent heat transfer coefficient.

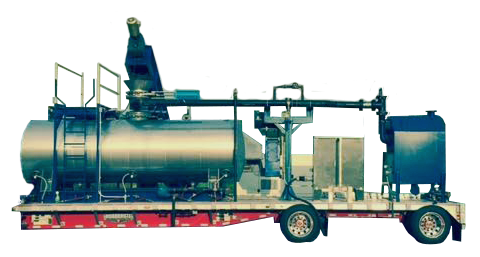

Mobile Sterilization System

The ANCO Mobile Sterilization System is designed to safely dispose of poultry, cattle, swine, sheep, deer, and more. This self-contained unit sterilizes the material at 45 psi and can be dispatched to any location without any environmental impact. The Mobile Sterilization System enables the operators to use the sterilized fat and protein for animal feed, fertilizers, or fuel. Each unit can be customized to meet customer’s needs and specifications.