PUMPS AND CONVEYORS

Offering the most outstanding pump technology in the industry

ANCO offers a wide range of pumps and conveyors solutions. Our equipment is designed to convey material from one process step to the next.

Lamella Pump

ANCO’s Lamella Pump proves an excellent solution for meat, fish, poultry, pork beef, and other semi-solid products. This unit also handles a variety of product sizes, from very small to coarse, and includes chunked meat, meat with high bone content, fats, slurries, and sludge with high solids content. The Lamella Pump’s high efficiency, low-maintenance pump design utilizes impeller vanes rotating in a cam motion, offering unique advantages over traditional pumping methods. The Lamella Pump features:

- Easy maintenance, through simple and fast access to all wear components.

- Patented design.

- Capability to process large or hard material.

- Special hardened wear parts made in H 600 and H 500.

- Welded or casted pump housing with GGG60 construction.

- Replaceable knives in the inlet and outlet of the pump.

- Pumping pressures up to 290 psi.

Two year warranty on each pump, motor, and drive assembly. - Optional feed screws, auto-reverse feature to clear blockages, 304 and 316 U.S.D.A. approved designs, heating or cooling jackets, and clamp design for daily cleaning.

- Ability to be supplied as a bare pump or a complete assembly, with frame and drive.

Screw Conveyor

All ANCO Screw Conveyors are constructed from the highest quality helicoid flight type, made of helix, and formed from a flat steel bar mounted on a pipe or shaft. Our experienced engineering department will prepare layouts and specify suitable types of trough, pitch, discharge, spouts, covers, and drives to fit your requirements.

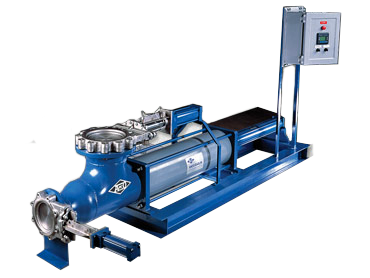

1208 Piston Pump

The ANCO 1208 Piston Pump is one of the best hydraulic pumps in the rendering industry and is used to process inedible, raw materials. All 1208 Piston Pumps feature:

- Up to 36,000 lbs. per hour from a single unit.

- Quicker load times.

- Chrome lined steel cylinders, providing lasting durability.

- Ability to pump difficult materials, such as viscera, bones, fish, pork, poultry, and much more.

- Minimal maintenance and a user-friendly design.

224 Fat Pump

The ANCO 224 Fat Pump is especially designed to transfer lard, greases, and oils in rendering plant environments. ANCO’s fat pumps include:

- Capacities up to 100 gpm+.

- Low HP requirements.

- Coupled and mounted gear motor.

- Rugged gear design for uniform flow.

- Optional stainless-steel housing design.

- Ability to accommodate complete plant automation with PLC.

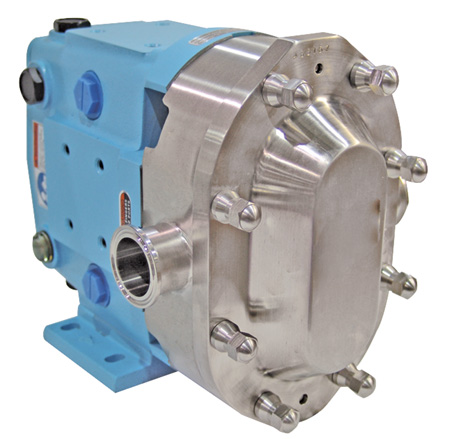

Waukesha Sanitary Pumps

ANCO offers a complete line of Waukesha Sanitary Pumps and Parts. These pumps are specifically designed to meet the needs of the meat, food, dairy, beverage, pharmaceutical, automotive paint, hydro-carbon processing, and coatings and adhesives industries. ANCO offers Universal Series Positive Displacement Pumps, Positive Displacement Lobe Pumps, and Centrifugal Pumps with several models and features to choose from. Users of Waukesha Pumps benefits from years of continued improvement, steady advances in design, metallurgy, and fabrication techniques that have yielded higher performance levels and service life. Waukesha Pumps have been setting the standard for over 50 years. ANCO offers standard models, rectangular flange models, high capacity models, and aseptic and bio-pharmaceutical models. Each unit features:

- Easy disassembly and maintenance.

- Flexible, three-way mounting.

- Exclusive, non-galling Waukesha 88 alloy rotors.

- 200 psi maximum pressure.

- -40 °F to 300 °F temperature range.

- Select models include operating pressures up to 500 psi, bi-directional flow, and tri-lobe rotors.